Additional Service Options

On site user training

When new owners or users take possession of a biomass system the need to be trained is essential to get the most from your system. We also offer more advanced, in-depth training for those who want to be in total control.

System health check and report

We offer a full visual and where possible an operational inspection and report. This includes systems designed and installed by other third parties, which you feel are under performing or not reaching quoted outputs. We can supply either basic reports or a more comprehensive full report as an option.

Flue Sweeping

Our fully trained, HETAS registered engineers, use the very latest in flue cleaning technology to give your flue a thorough service, including a visual inspection of the liner, ash bins and de-ashing systems are also cleaned and inspected for wear.

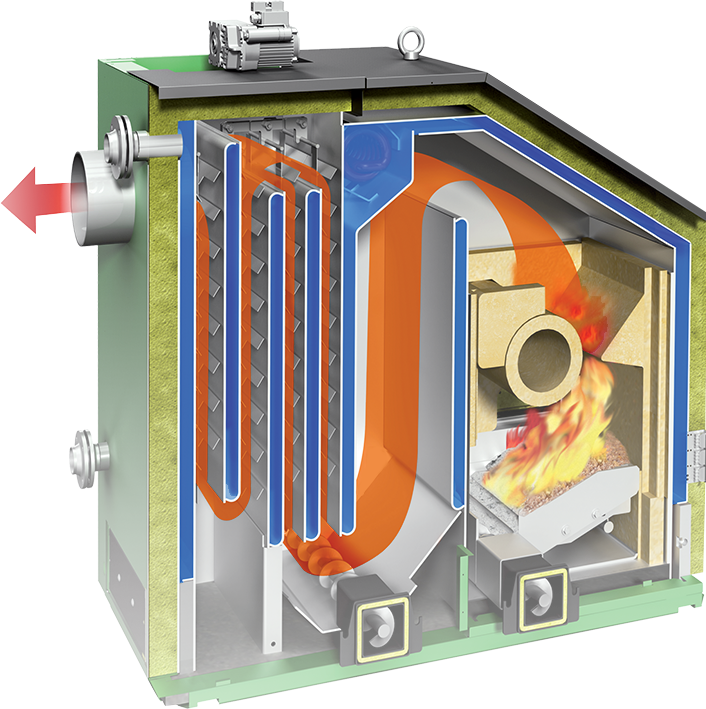

For larger boilers with fly ash removal systems, the turbulators and internal channels of the actual boiler are cleaned and inspected.

Additional charges may apply if suitable access has not been installed for our engineers to gain access.

Power Flushing

A power flush is a process used to clean and maintain the internal components of a biomass boiler. The process involves forcefully pumping a mixture of chemicals and water through the boiler’s system to remove any buildup of debris or sludge.

A power flush is an effective way to remove this buildup and restore the efficiency of the boiler. The process begins by connecting a power flushing machine to the boiler’s system. This machine uses a combination of chemicals and water to clean the system, breaking down and removing any debris or sludge that has accumulated, allowing the boiler to operate more efficiently and potentially reducing energy costs.

Descaling

To accompany the power flushing of the water system within the boiler, descaling with chemicals can dissolve the calcium deposits that can build up within the internal water ways, pipes and heat exchangers with the body of the boiler, removing this build up allows the boiler to operate more efficiently and potentially reduce energy costs.

Inhibitor Testing

Once the system has been flushed and descaled, the inhibitor solution can be checked for the correct concentration, and if found lacking can be topped up to the desired concentration or completely refreshed with new inhibitor.